That Mavericks "feature"

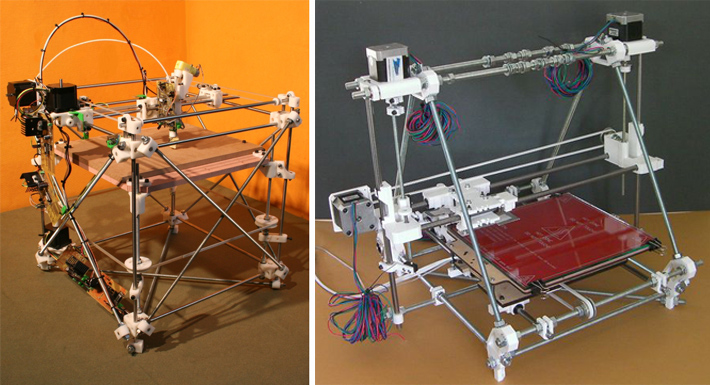

If you have upgraded to Mavericks, you've probably been enjoying the extended battery life. However, if you've also been printing, you probably haven't enjoyed the impact the upgrade has had on using Printrun in the background. To fix the issue, find Printrun in your Applications folder, choose Get Info by right clicking on its icon, and check Prevent App Nap.

Restart the app, if necessary.

Windows users... victory pose!

Printable tool research show and tell

Let's take a look at everyone's tool and hear about their experiences with it.

Please email me the brief writeup and images documenting your experience before leaving today.

New materials

We have some new printable materials to experiment with in class:

- Glow in the dark PLA (Normal PLA settings)

- Thermochromic PLA (Turns yellow when temperature exceeds 91.4º F, Normal PLA settings)

- Soft PLA (Extruder: 200-230º [make sure no fan is on at lower temp], Bed: No heat needed) More info...

- Laywoo-D3 aka "wood filament" (Extruder: 175-250º [higher temperature results in darker print], Bed: No heat needed, Nozzle: 0.5 and higher) More info...

- Laybrick aka "stone filament" (Extruder: 165-210º [make sure to use a fan at higher temperatures], Bed: No heat needed, Nozzle: 0.5 and higher) More info...

Reference objects

Print a small object* which can be printed in each of the new materials introduced today.

- *Multiple objects will be fine if you feel like experimenting with different kinds of forms (solid vs. hollow, for example) or characteristics of a printing material.

- Maximum of 25mm in largest direction, unless you are planning on printing something quite skinny (10mm or less) and need extra length.

- Remember, round things are measured in OpenSCAD by radius, so the maximum would be 12.5mm.

- Be sure to make notes on your printer settings.

Disabling the fan but keeping the layers cool

The Slic3r profiles are set up to automatically turn on the fan. While this is great for PLA, it's not so good for higher temp materials (ABS, soft PLA). To stop the fan (without modifying the custom gcode for the printer):

- Filament Settings > Cooling > uncheck Keep Fan Always On

- Do not uncheck Enable auto cooling. This will automatically slow down your print to cool as needed. Trust me, it is needed.

- Stop the fan by entering a M107 command in Printrun when your print begins.

- Enter another M107 when your bottom shell finishes (you should notice a change in speed when it begins infill).

Adding buttons to Printrun

Let's face it, entering M107 manually kind of stinks, so let's create a button which we can press to kill the fan.

- Underneath the layer preview window you will see a little button with either a . or a + on it (apparently, it may also be blank). Click it.

- Title your button FAN OFF

- Add the M107 command to the Command field

- Ignore color, unless you are on Windows.

- To add a "fan on" button, use the command M106 S255.

Project 2: Highly Functional (Due Nov. 25th)

Thomas Thwaite's toaster

This project can be completed with a partner or by yourself. See details of partner version below.

Create an object which serves a specific function in your life. The object must be composed of two different printed materials, but supplemental non-printed materials may also be used.

Some things to consider:

- How does your object differ from pre-existing/manufactured objects which have related functionality?

- Which materials should be used to make this object? How do the specific properties lend themselves to their use.

- While the object must be functional, it does not need to be practical (It must work, but its design can be informed by other issues related to its use.)

Partner version

Create a parametric version of the functional object. The parameters (minimum of two) should have a clear, intentional impact on the object's use.

Two different printed versions must be presented in class.

Schedule:

- Nov. 11th: Begin ideation. Material testing.

- Nov. 18th: Work session. Discuss project plans.

- Nov. 25th: Project presentations. Becky Stern talk and class visit.

- Dec. 9th: Project documentation due. All code licensed and pushed to GitHub.